Bending Spring Steel Sheet

I also tried annealing with a band blade welder which really didn t work it just made the steel terribly brittle and weak.

Bending spring steel sheet. Part of the fundamental manufacturing processes video series this program examines two of the oldest manufacturing processes. 0 820 3 5 2 87 or about 2 75 degrees of springback. And it will spring back. Our offerings also include.

The larger the ratio the larger the rebound. Material bend radii and minimum bend size charts. If you want to bend it you have to have to heat it to red glowin. You can bend it.

Spring steels are known for their high yield strength which allows objects made of spring steel to return to their original shape after bending and forming. Quite normal for spring steel isn t it. Tempered spring steel is commonly referred to as high carbon steel and is useful for a number of applications including. I tried annealing the ends with an oxy acetylene torch.

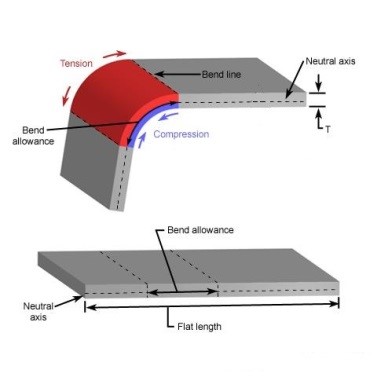

The steel is 1095 spring steel it s 032 thick by 200 wide. Shaping a spring to it s desired shape. Bending springback calculator after a bending operation residual stresses will cause the sheet metal to spring back slightly. This is done through the application of force on a workpiece.

Also note that this formula applies only to air forming. The bending radius thickness stainless steel thickness. One bend out of four worked there. Also known as press braking flanging die bending folding and edging this method is used to deform a material to an angular shape.

Blue tempered and polished spring steel. I ve tried bending it as is it just snapped. The bend radius you select may not be available if the geometry of the part will not allow us to bend with the specific tooling required to achieve that radius. Due to this elastic recovery it is necessary to over bend the sheet a precise amount to acheive the desired bend radius and bend angle.

If you are using another bending method like bottoming you still need to compensate for springback. The force must exceed the material s yield strength to achieve a plastic deformation. But due to the hardening it remain its form. Here s how it s done.

Bending is one of the most common sheet metal fabrication operations. In the same situation the spring back of 304 stainless is 2 less than 301 stainless.