Bending Sheet Metal Hardness Or Yield Strangth

For example take the vickers number which has the dimension kg mm2 and multiply by 10 to approximately convert it to mm2 mpa then divide by three.

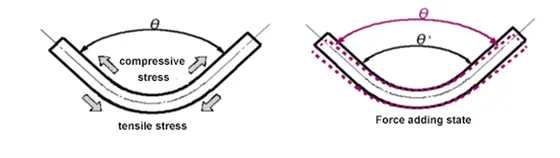

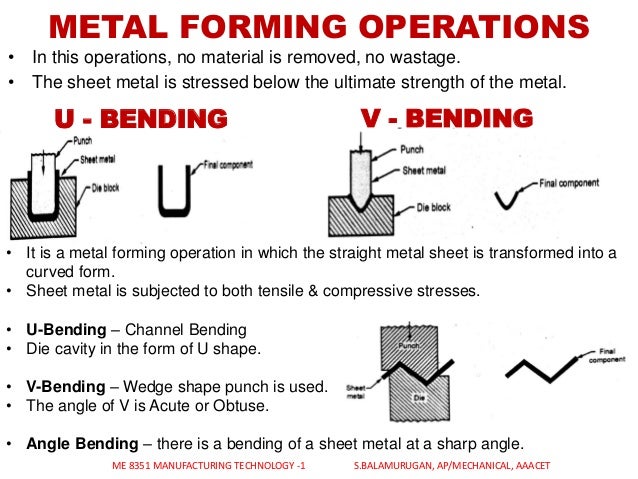

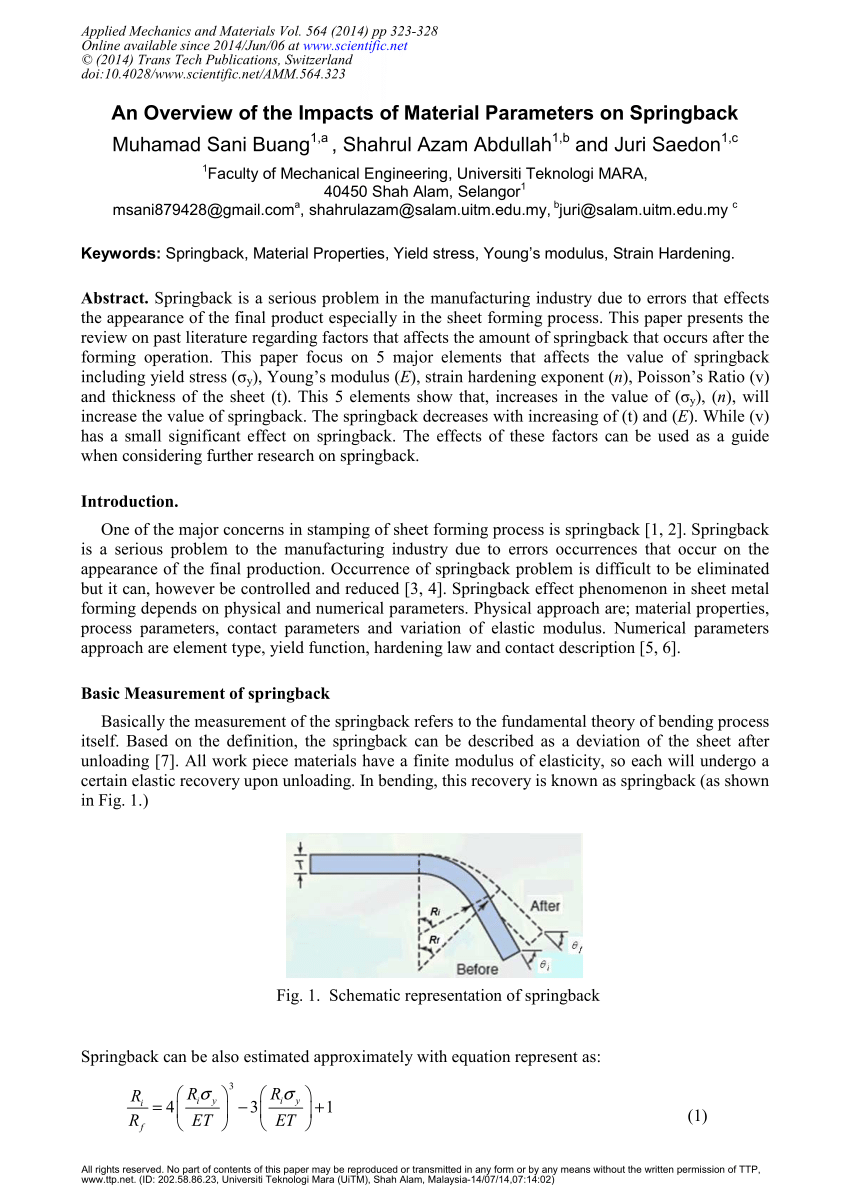

Bending sheet metal hardness or yield strangth. The yield strength in tension is about 1 3 of the hardness. Generally as supplied materials annealed at the haynes international mills have sufficient ductility for mild forming. This distorts the steel s grain structure which increases its hardness and tensile strength while decreasing ductility. The greater the yield strength of the material the greater the spring back and the smaller the angle of the punch die should be designed for the angle of 90 degrees of the bending part.

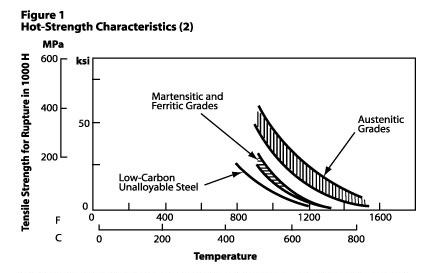

Yield strength tensile strength and ductility values for steels at room temperature. It is the maximum stress that the cross section is subjected to when the load is applied between the two points of the. Aisi 304 grade stainless steel uns s30400 aisi 304 stainless steel uns s30400 is the most commonly used material in stainless steels and is usually purchased in an annealed or cold worked state. 2 stress strain curve showing total elongation.

After a piece of tempered sheet metal or aluminum is worked with a hammer for a while it begins to get hard and brittle so you may need to temper it again to be. Sheet metal fabricators and hammer formers deal with this too. However for higher levels of cold deformation where cracking is a possibility due to a reduction in ductility a series of successive forming operations is recommended each followed by an intermediate annealing treatment. Offset yield strength and yield by extension under load eul were developed total elon tion offset yield stren yield strength fracture 2 byeul pgortional limit a en neerin strain e fig.

Compared to carbon steel for the same thickness of stainless steel the bending angle is larger special attention should be paid to this point otherwise. I ve avoided cracking by having a large radius relative to the material thickness. It is one of the indexes of metal strength. The alloy composition of the material is important as well since the addition of alloying elements can significantly affect the mechanical strength of a material.

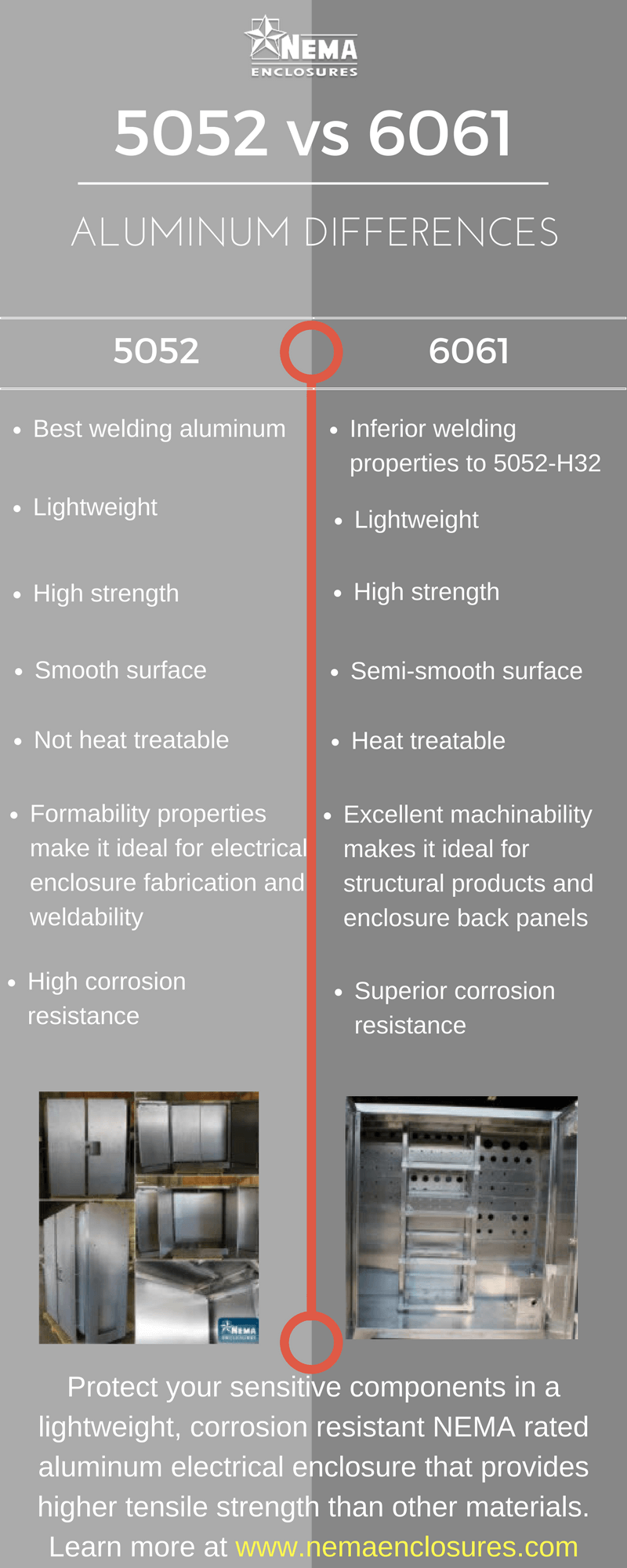

1 automobile bodies such as this ford 500 are dependent on the ability ofsheet metal to. In my 40 plus years in the trade i have bent quite a lot of 6061 t6 aluminum. Tensile yield strengths and ductilities for some of the plain carbon and low alloy steels are given in the following mechanical properties of steel chart. It is the maximum stress that the sheet metal material is subjected to before pulling out.

And i ve sometimes performed a three step bend a 2 degree bend in front of the bend centerline a 2 degree bend from behind the bend and then an 86 degree bend in the center. To find the ball park figure for the yield strength convert the hardness number to mpa or psi and divide by 3.