Bending 3mm Aluminium Sheet

The k factor is the ratio of the neutral axis location t to the material thickness mt.

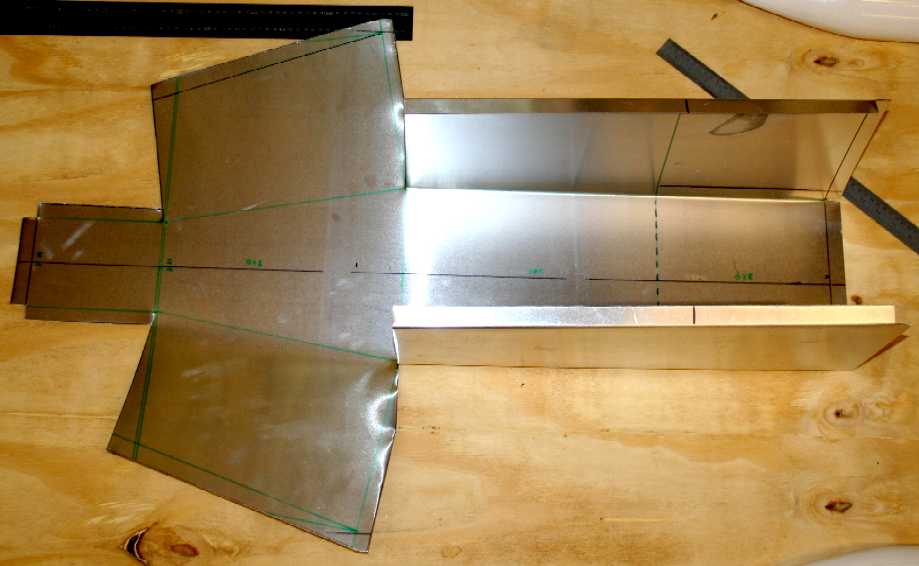

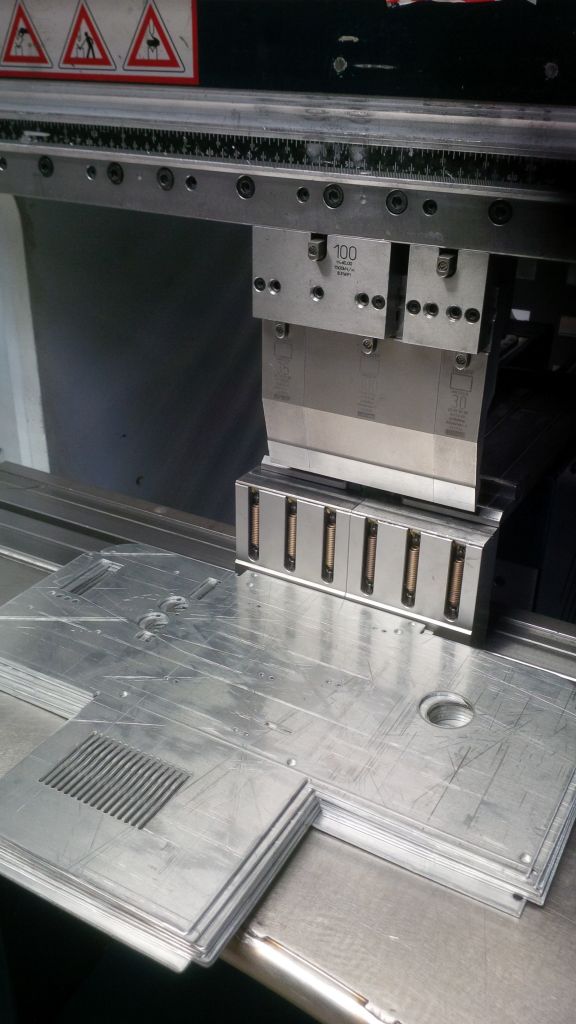

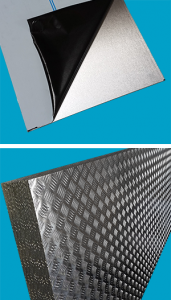

Bending 3mm aluminium sheet. 9th may 2012 03 39 pm 1. Figure 1 when you bend sheet metal the neutral axis shifts toward the inside surface of the bend. The bend radius you select may not be available if the geometry of the part will not allow us to bend with the specific tooling required to achieve that radius. Can i bend 3mm aluminium sheet at home.

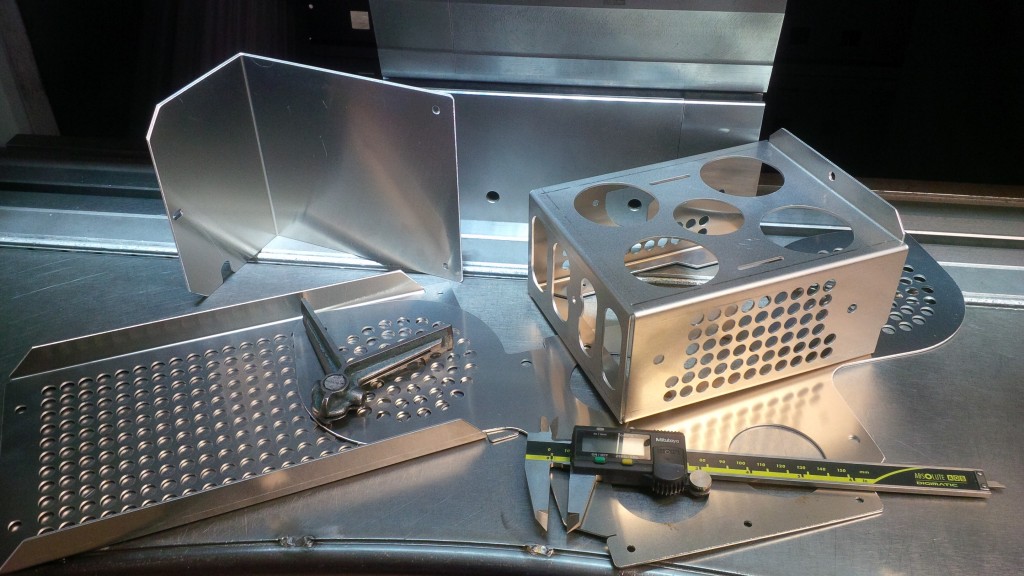

Material bend radii and minimum bend size charts please note. But actually getting precise bends and keeping everything square would also be a challenge. I thought about this for a few days. This is done through the application of force on a workpiece.

With the aid of a straight edge and a sharp knife score both sides of the aluminium sheet. This is a highly technical and potentially dangerous process best left to a professional metalworker. I had a question on k factors for our 3 d modeling software. Results 1 to 10 of 16 thread.

Use the minimum bend dimension values in the charts below for your minimum closeness of cutout to a bend. I wanted perfect bends and bending 3mm aluminium wasn t going to be easy. In principle does not seem that this operation is complicated and difficult. Sheet aluminium can be cut without the need for a guillotine or tin snips which tend to deform the metal.

60 90 and 120 and we will calculate k factor bend allowance and bend deduction for them. Our design engineers typically use a factor of 0 4 for our air formed press brake parts. The one thing i was certain about. Heavy gauge aluminum bars or rods must be heat bent using an acetylene torch and vice.

The bending of sheet metal with a punch and an array mounted at a folder is quite natural and normal. Bending is one of the most common sheet metal fabrication operations. We are going to review three bending scenarios with three different bending angles. Also known as press braking flanging die bending folding and edging this method is used to deform a material to an angular shape.

Can i bend 3mm aluminium sheet at home. Join date jan 1970 location. The force must exceed the material s yield strength to achieve a plastic deformation. You have to factor in how much material the bend will use and where it will end up.

Place the fracture line over the edge of a table and bend the overhang slightly downwards. This weakens the aluminium and creates a fracture line. Page 1 of 2 1 2 last.