Bending 2024 T3 Aluminum Sheet

Annealed sheet can be bent to a radius approximately equal to its thickness.

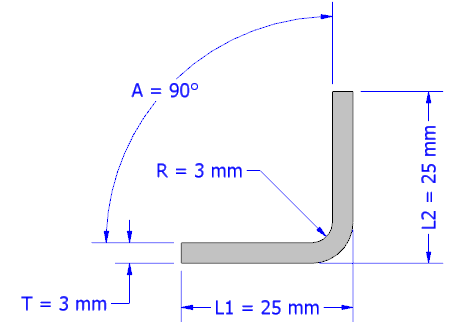

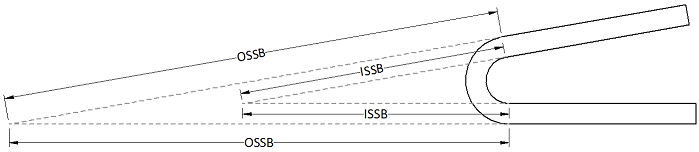

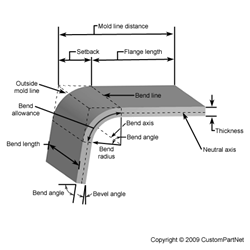

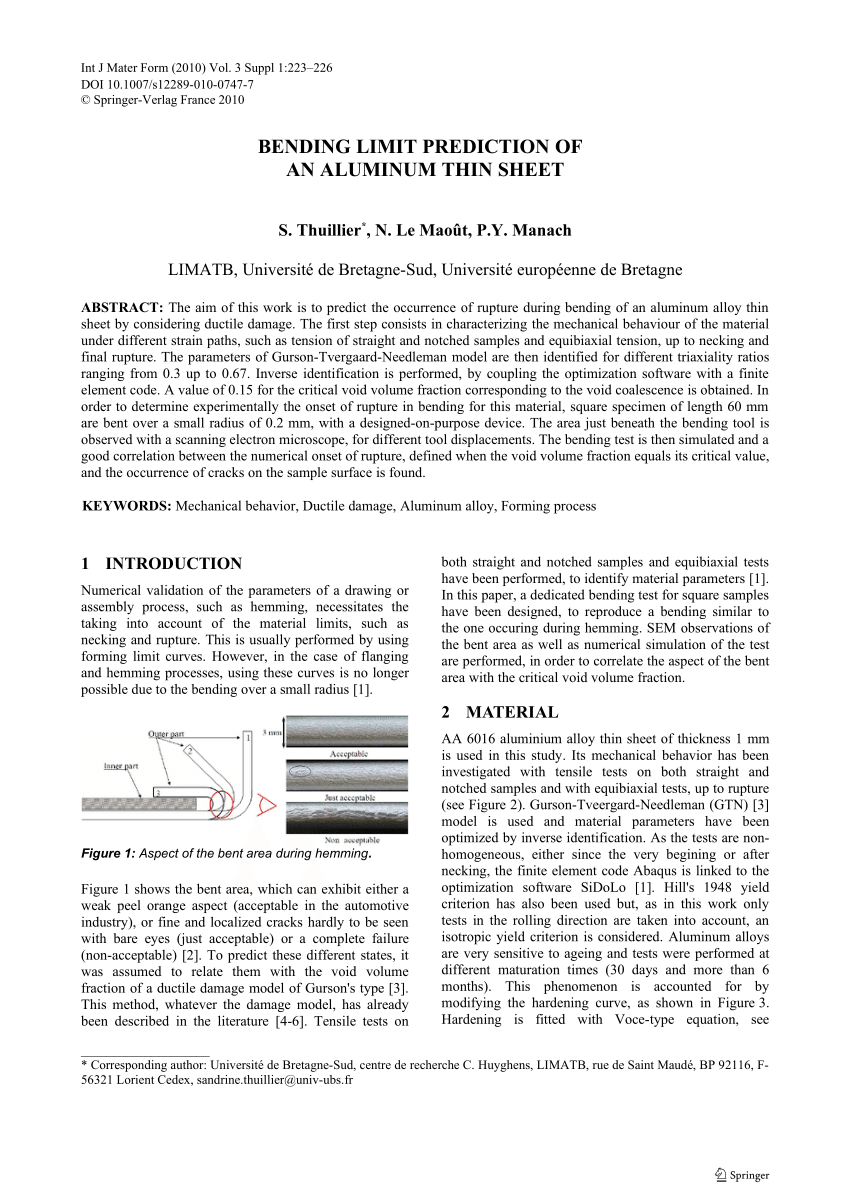

Bending 2024 t3 aluminum sheet. I have formed 032 2024 t3 sheet in a similar brake with the correct nose radius inserts and spent a lot of time dialing in the brake to get an acceptably straight bend line. The minimum bend radius is affected by the kind of material thickness of the material and temper condition of the material. Understanding the bend allowance and consequently the bend deduction of a part is a crucial first step to understanding how sheet metal parts are fabricated. As this happens you gain a small amount of total length in your part.

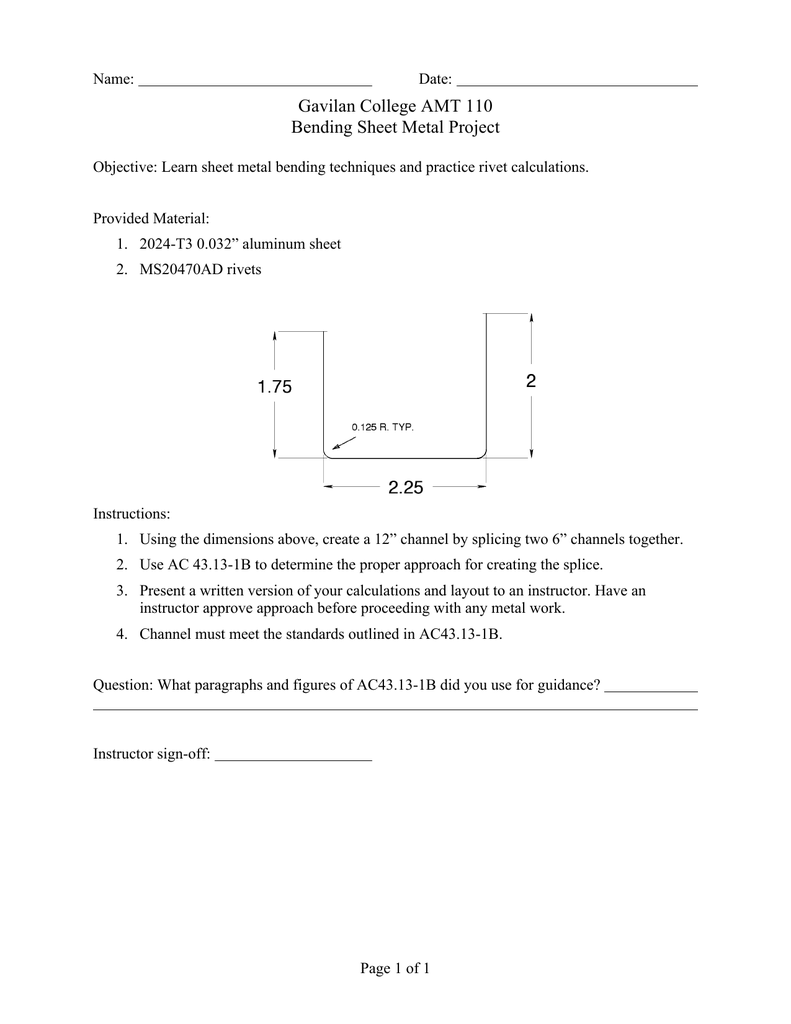

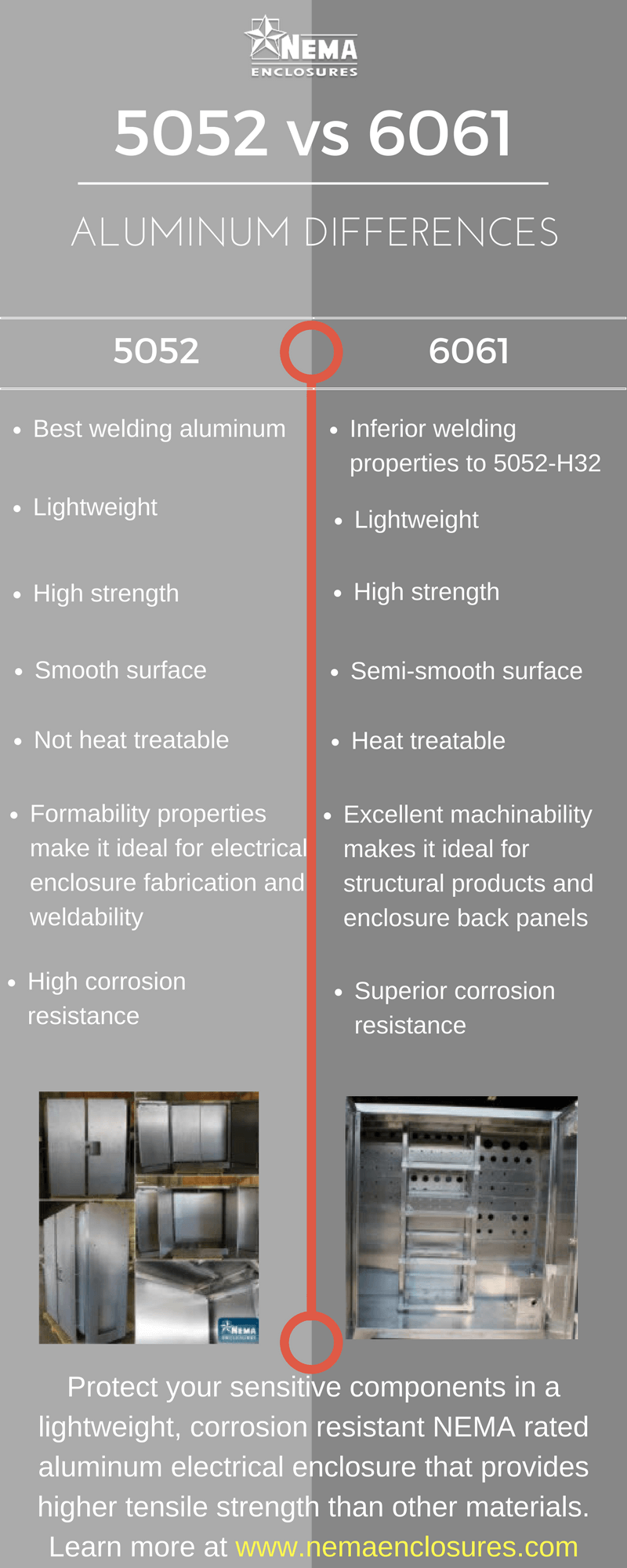

There will be four 90 bends. The following alloys are all available in my chosen thickness of sheet stock. 2024 t3 5052 h32 6061 t6 my parts will be stamped to roughly 1 2 x 3 4 and then formed in a series of stations. Any time a different thickness of sheet metal needs to be formed or when a different radius is required to form the part the operator needs to adjust the sheet metal brake before the brake is used to form the part.

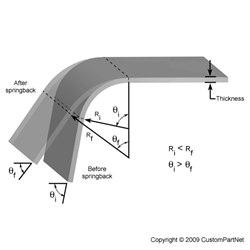

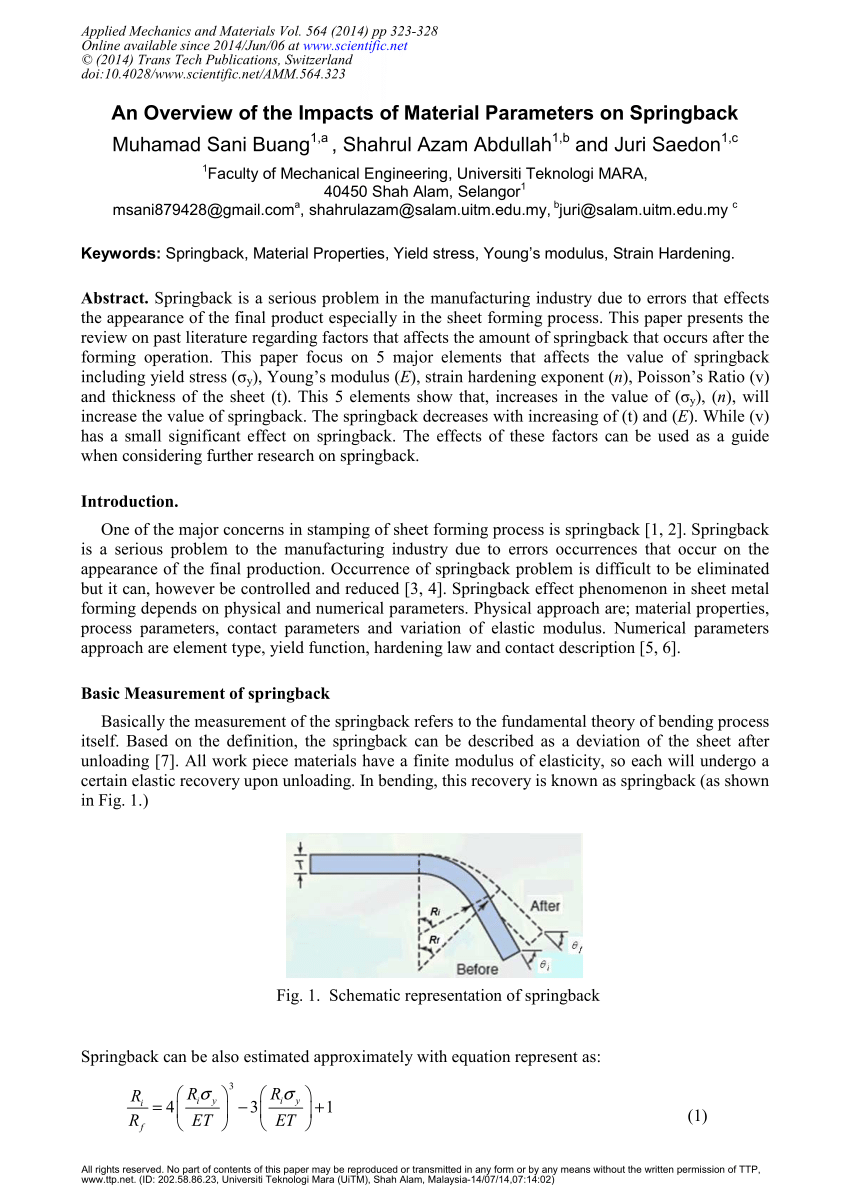

The minimum bend radius data shown in these charts is measured to the inside of the bend. Order by part number. Just asking advice on which alloy will bend well crack the least and when bent stay that way with minimal springback. From non heat treatable 3003 and 5052 to the heat treatable 2024 6061 and 7075 you have many options from which to choose.

2024t3 alclad aluminum sheet aluminum alloy sheet is sold in the thicknesses and sheet sizes shown in the table. Minimum sheet size available is 2 x 4. The bend radii listed are standard minimum if manufacturing for aircraft and aerospace applications. Stainless steel and 2024 t3 aluminum alloy require a fairly large bend radius.

With 2024 t3 040 sheets is there plastic on both sides for protection as you noted is the case for 2024 t3 025 sheets. There was a lot of deflection in the brake itself at this thickness definitely pushing its capacity at only 032. Clinton aluminum offers a variety of products each covering a wide range of applications and processes. When the sheet metal is put through the process of bending the metal around the bend is deformed and stretched.

I work at an aerospace company and i need to bend aluminum parts 6061 t6 and 2024 t3 alloys of different thickness in three groups.