Bending 1mm Aluminium Sheet

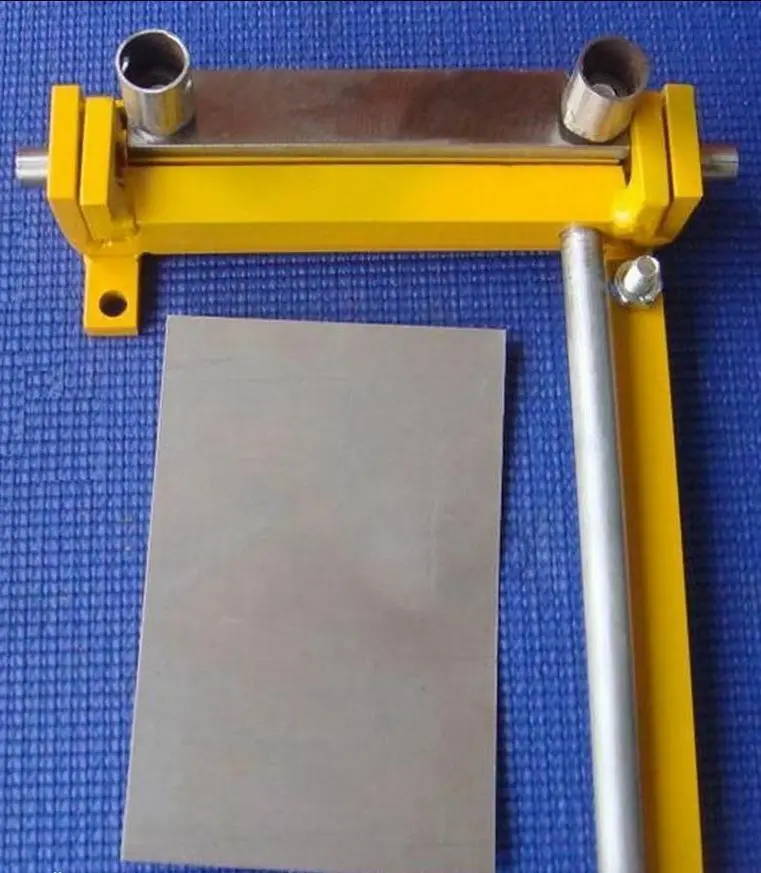

Clamp the wood on top of the metal to the workbench.

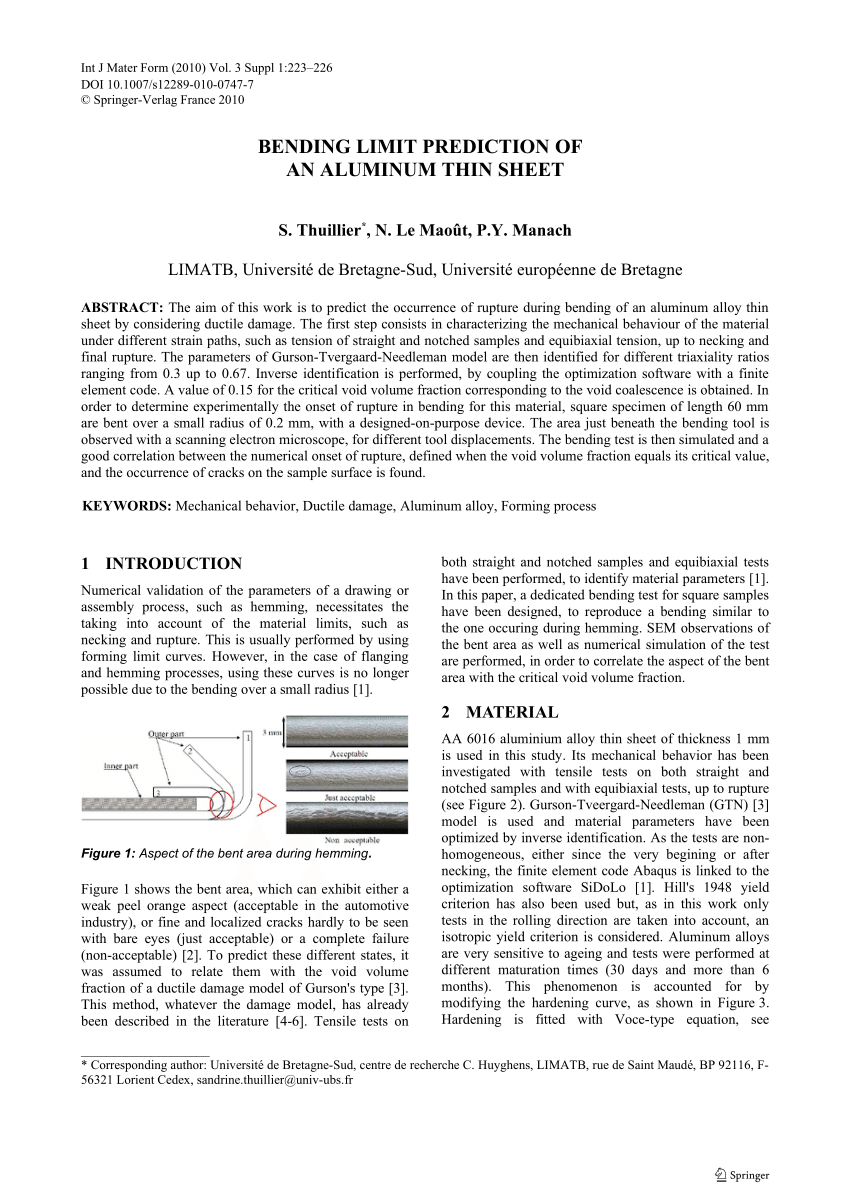

Bending 1mm aluminium sheet. How to bend sheet metal without a brake. Free delivery with 45 order. Mark a bend line and place the sheet metal on the edge of your bench. How to bend sheet metal without a brake in 4 different methods with minimal or homemade tools.

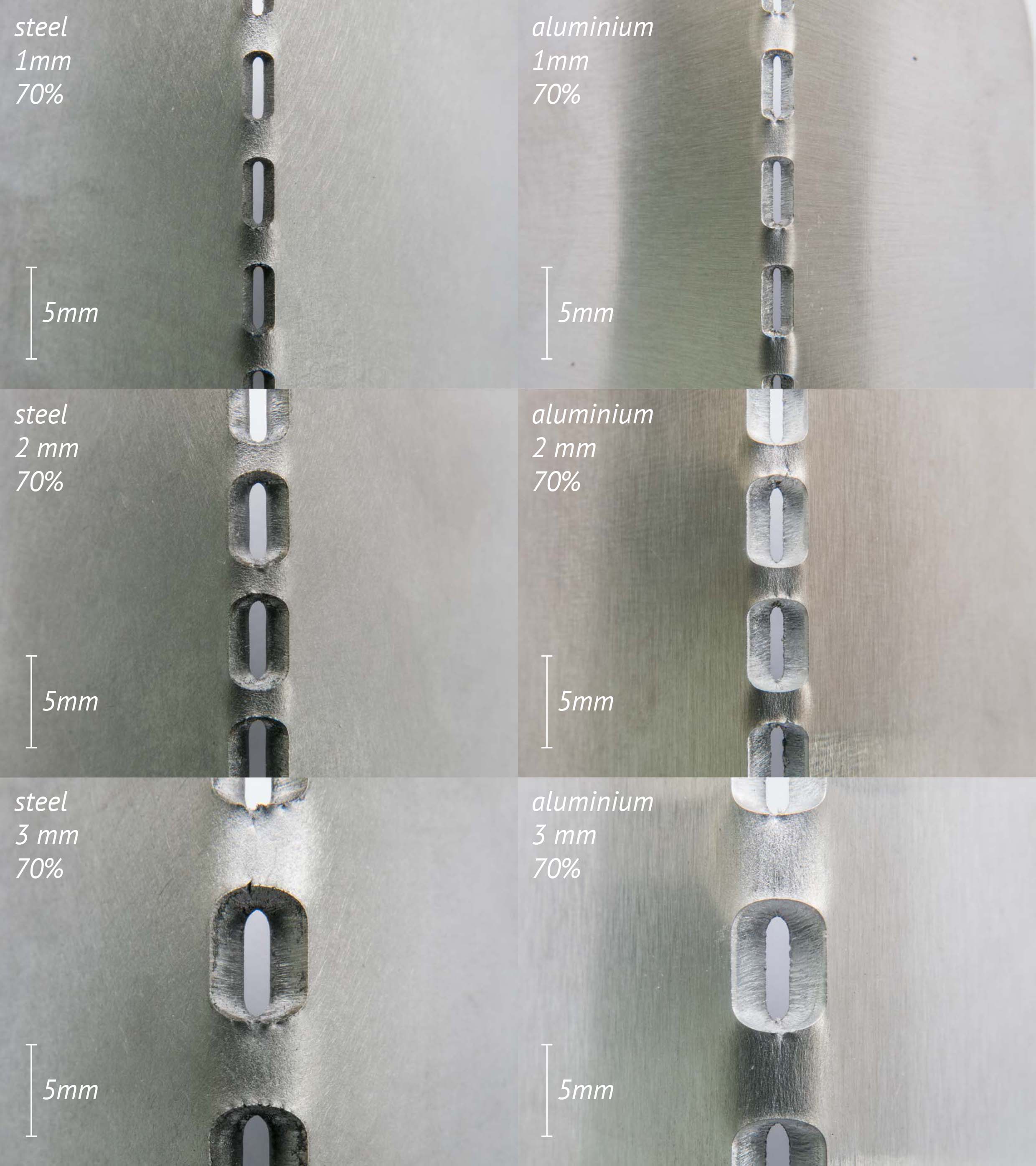

Bending is a delicate and demanding process most of the time and common fabricating processes require a degree of formability that make your choice of proper alloy critical. Use the minimum bend dimension values in the charts below for your minimum closeness of cutout to a bend. Finally bend the sheet up by hand to the angle desired. M d building products 12 in.

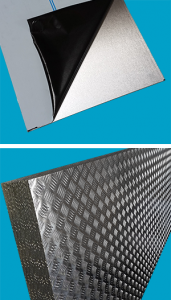

3003 h14 aluminum sheet astm b209 qq a 250 2 excellent weldability and formability with good corrosion resistance makes 3003 aluminum sheet a popular and economical choice. The force must exceed the material s yield strength to achieve a plastic deformation. Diamond tred aluminum sheet heavy weight model 57575 13 49 13 49. Material bend radii and minimum bend size charts please note.

Most frequently expensive sheet metal bending tools called brakes are used to bend sheet metal but you can also complete this task without one. This is done through the application of force on a workpiece. Which aluminum alloy bends the best is a a common question customers want the answer to. M d building products 1 ft.

Bending is one of the most common sheet metal fabrication operations. Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. In this post we ll explain it to you. This weakens the aluminium and creates a fracture line.

Mill finish not polished. With the aid of a straight edge and a sharp knife score both sides of the aluminium sheet. Flip the sheet over and repeat. In high purity forms aluminum is soft and ductile.

Fuel tanks food chemical handling trailer siding roofing etc. 3003 aluminum sheet has a smooth semi shiny finish and is popular for many applications including. Next place the wood parallel and slightly behind the bending line. Place the fracture line over the edge of a table and bend the overhang slightly downwards.

Set your store to see local availability compare.