Bend Aluminum Sheet Smallest Radius

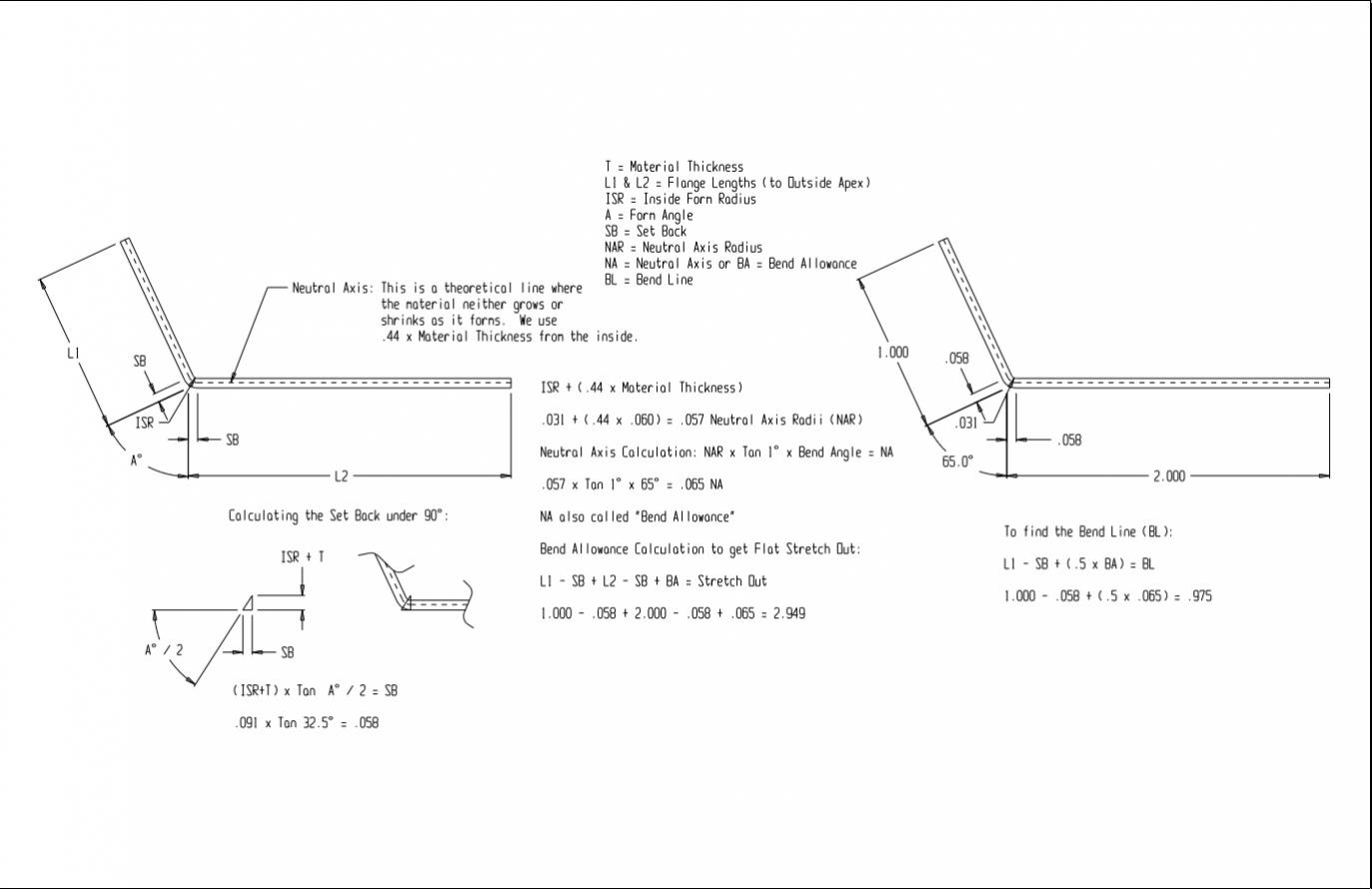

The bend radius you select may not be available if the geometry of the part will not allow us to bend with the specific tooling required to achieve that radius.

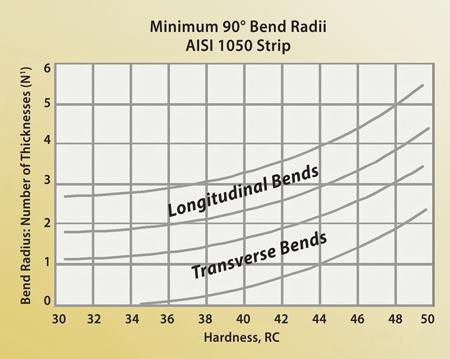

Bend aluminum sheet smallest radius. 5052 h32 aluminum bends in about the same way as mild steel. The bend radii listed are standard minimum if manufacturing for aircraft and aerospace applications. Brittle metal such as aluminum generally requires a larger bend radius than ductile material like cold rolled steel. It requires an inside bend radius of at least 6x the material thickness.

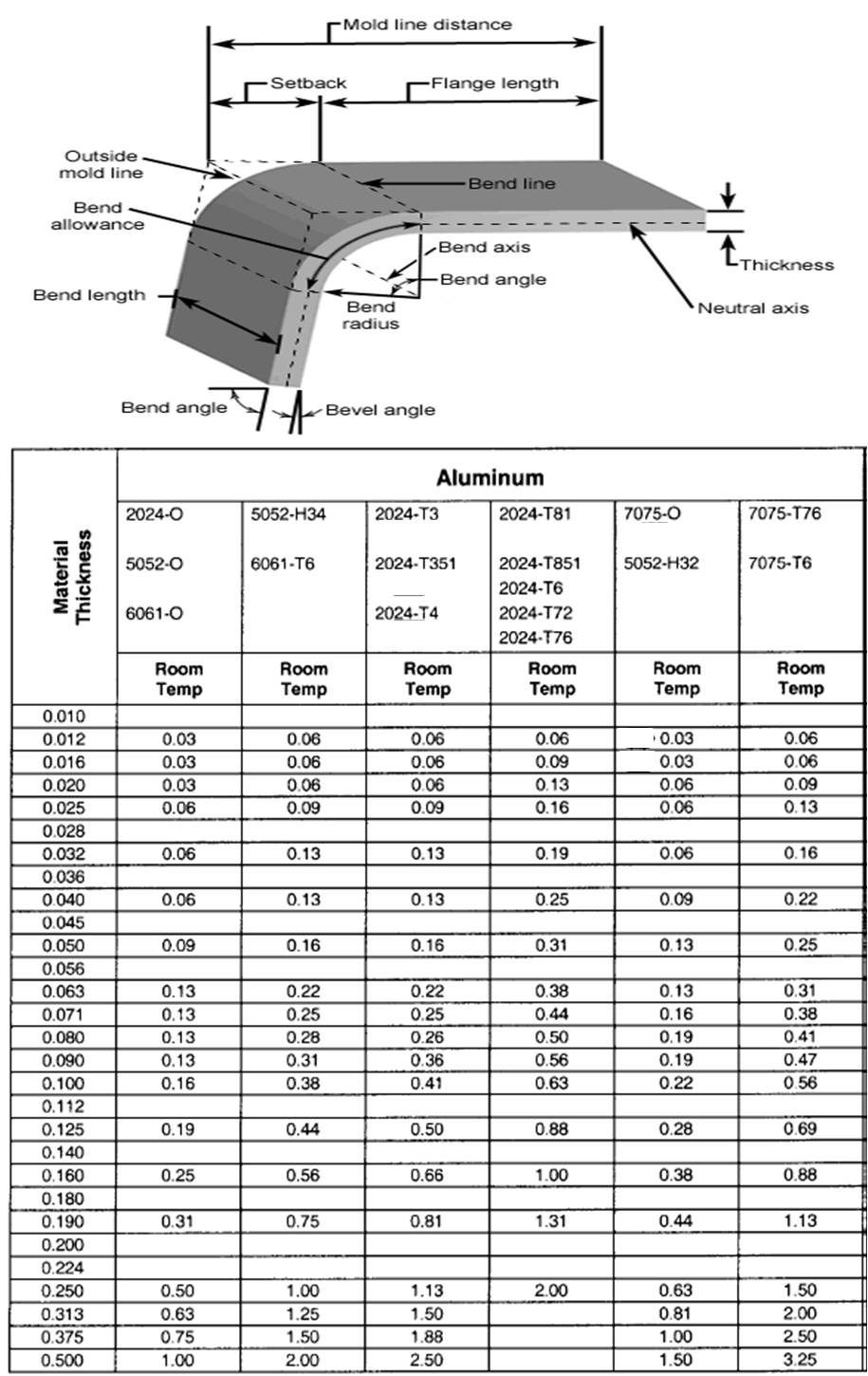

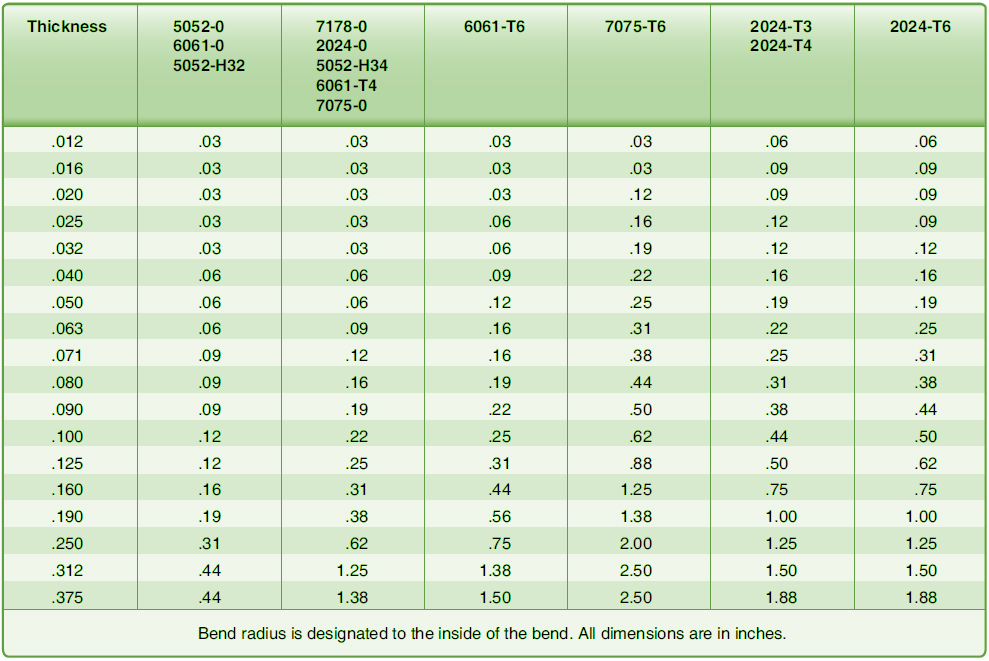

Radii for various thicknesses expressed in terms of thickness t. We recommend printing it out to keep as a reference. Aluminum minimum bend radii for 90 degree cold forming of sheet and plate. The harder and thicker the plate is the greater the minimum bend radius.

The trend is obvious. The problem with bending too tightly. It is possible to choose other bends if you require but additional lead time and tooling charges may apply. X research source basic bending brakes typically retail for around 20 50 and are small enough to fit easily on most work benches or tabletops.

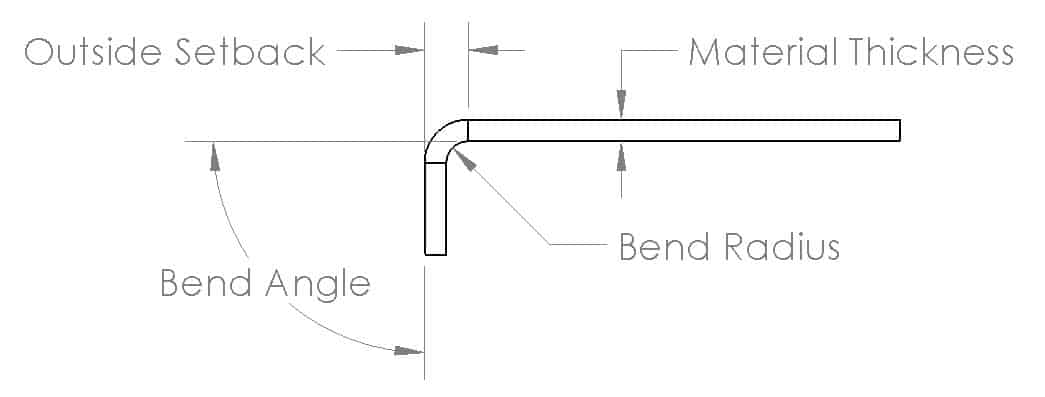

The most common problem with bending a piece of sheet metal too tightly is. Since commercial sheet metal bending can be done with less concern for stresses caused during forming operation the radius can be near zero for thin sheet metal. Each and every bend in a piece of sheet metal has a certain minimum internal radius that needs to be taken into account when planning the design of a sheet metal form. For 0 5 in thick 7050 aluminum the minimum bend radius may be specified as much as 9 5 times material thickness.

The minimum bend radius data shown in these charts is measured to the inside of the bend. We go beyond the general rules of sheet metal bending as our customers want tight bend radii for sheet metal parts. This is done through the application of force on a workpiece. The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by protocase.

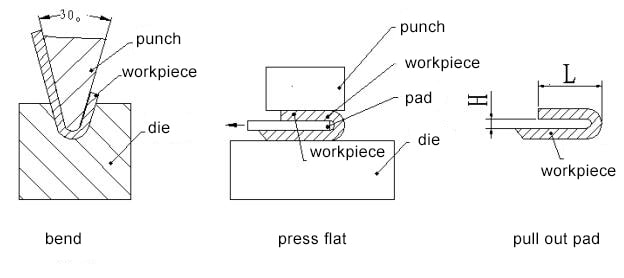

3003 h14 is extremely ductile. The force must exceed the material s yield strength to achieve a plastic deformation. When working with aluminum over sheet metal several variables need to be considered. Bending is one of the most common sheet metal fabrication operations.

For example 6061 t6 aluminum is very difficult to bend. Per the aluminum association inc. Aluminum is typically thicker and stronger and requires more force to bend as well as consideration of edge conditions and punch nose radii. If your bend radius needs to be adjusted a member of engineering design services team will contact you before your design is manufactured.

This free chart outlines what bend radii is required for the approximate thickness of aluminum. Also known as press braking flanging die bending folding and edging this method is used to deform a material to an angular shape.